X-ray Fluorescence Analysis

Julia Martín[math]^{1,\dagger}[/math], María José Navas[math]^{2}[/math], Ana María Jiménez[math]^{2}[/math] and Agustín G. Asuero[math]^{2}[/math]

[math]^{1}[/math]Department of Analytical Chemistry, Escuela Politécnica Superior, University of Seville, 41011-Seville, Spain, EU.

[math]^{2}[/math]Department of Analytical Chemistry, Faculty of Pharmacy, University of Seville, 41012-Seville, EU.

[math]^{\dagger}[/math] Corresponding Author.

An overview of XRF (X-Ray Fluorescence) is given, mainly paying attention to the X-ray production process, XRF instrument configurations, sample handling, matrix effect and quantitation, development and challenges, and applications.

Contents

1 Introduction

X-ray science has a prosperous history. Wilhelm Konrad von Röntgen, a German physicist and rector of Julius Maximiliam Wurzburg University (Assmus, 1995; Dörfel, 2010; Hurwic, 1980; Seliger, 1995), at age 50 made the accidental discovery of X-rays on the evening of Friday the eighth of November 1895, while working in the dark with cathode rays (gaseous discharge Crookes tube at high voltages). He called them “X rays” because he did not understand their origin. This name prevails in English-speaking areas, whereas the name “Röntgenstrahlen” is used in German speaking parts in honour of Röntgen. For his discovery, in 1901, Röntgen was awarded the first Nobel Prize in physics. In Lennep, birthplace of Rontgen, located 50 km from Dortmund, was founded in 1932 the "Röntgen Museum". Six different Nobel Prizes were awarded (Galli, 2014; Palmer, 2011) in the early 1900’s concerning the topics of X-rays (discovery, diffraction, and spectrometry).

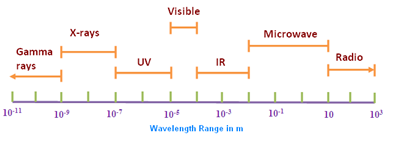

Many instrumental techniques are based on a continuous range of wavelengths (or energies) that nature provides (Anzelmo et al., 2013). The X-ray region occupies in the electromagnetic spectrum (Fig. 1) an area of high energy and short wavelengths, between [math]\gamma[/math]-rays and ultraviolet light, which range approximately from 0.012 to 31 nm (40 eV to 100 keV). The X-ray region may be subdivided (Dolenko et al., 2017) into short wavelength ([math]\lambda \leq [/math] 0.2 nm), long wavelength (0.2 [math] \leq\lambda \leq [/math]2 nm), and ultralong wavelength ([math]\lambda \gt [/math] 2 nm). Note that 1 nm = 10[math]^{-9}[/math] m and 1nm = 10 Å (Ångstroms). The medical field is where X-rays found its early applications (Mattsson and Börjesson, 2008; Mould, 1995). Within three months of Röntgen’s original publication (December 28th, 1895), X-rays were routinely used as an aid to surgery in a hospital in Vienna (Whiston, 1987, p. 4). The German dentist Walkhof presented the first dental radiography (Demirdjian, 2007) on January 23th, 1896, only two weeks after the communication of Röntgen to the Würzburg Physical Medical Society. The X-rays discovery, as well as their analytical applications, remained ignored until 1913, as we may see later. However, in the past 50 years or so, new applications such as the analysis or materials characterization have emerged.

There are a number of approaches (Jenkins, 2000a) to X-ray analysis. In X-ray absorption, the absorption of energetic X-rays, that occurs when an electron is removed from its orbital, is related to the concentration of absorbing species in the sample irradiated. A definite proportion [math] \left ( I/I_{0} \right ) [/math] of the incident radiation [math]I_{0}[/math] can pass through a layer of thickness [math]\tau[/math](cm) and density [math]\rho[/math] (g/cm[math]^{3}[/math]) (absorber), the wavelength [math]\lambda[/math] of the transmitted beam remaining unchanged. The intensity [math]I[/math] of the transmitted beam is given (Bouguer-Lambert-Beer law) by [math] I=I_{0}\exp \left ( -\mu \rho \tau \right )[/math], where [math]\mu(cm^{2}/g)[/math] is the mass absorption coefficient and the product [math]\mu\rho[/math] is the linear absorption coefficient [math](cm^{-1})[/math] (Thomsen, 2007). For a given element and wavelength, [math]\mu[/math] is a constant, independent of the chemical and physical state of the element. In many handbooks, monographs, on the web, and in research papers, tables of mass absorption coefficients at various wavelengths for different elements can be consulted. For example, the total mass absorption coefficient is given by [math]\mu _{T}=\sum \mu_{T}\; w_{i}[/math], where [math]w_{i}[/math] is the mass fraction of the ith element present in the sample. However, the mass attenuation coefficient (taking into account both X-rays absorption and scattering) should be used (Robinson, 2005) for accurate quantitative work. Undoubtedly the techniques of absorption are the least used of all those that use X-rays, although they are useful in some cases as in elemental analysis and thickness measurements.

In X-ray emission spectroscopy, the sample is bombarded with an electron beam in an X-ray tube and the emitted X-ray photons are measured. In practice, this technique is used poorly since the sample should be placed in the X-ray tube. Measurements are generally restricted to qualitative or, at best, semi quantitative determinations because of the heating and selective volatilization of different elements by the impinging electron beam. However, this is the basis of X-ray microanalysis using an electron microprobe or a scanning electron microscope.

In X-ray fluorescence, or secondary X-ray emission, the sample is bombarded with an X-ray (primary) polychromatic beam of short wavelengths, e.g. the continuous radiation from an X-ray tube, and the reemitted (secondary) X-radiation (of longer wavelengths) is measured. The wavelengths thus emitted are equal to those that result from excitation produced by electron bombardment. The difficulties found in using X-ray emission for quantitative analysis are not experienced in X-ray fluorescence (XRF) so this technique is widely used for analytical purposes and perhaps XRF is the most important of all X-ray analytical methods.XRF is really a surface technique since the primary beam doesn’t penetrate very far into the specimen, usually a few micrometres for a heavy element such as gold, and to about half a millimetre for aluminum, a lighter element (Whiston, 1987).

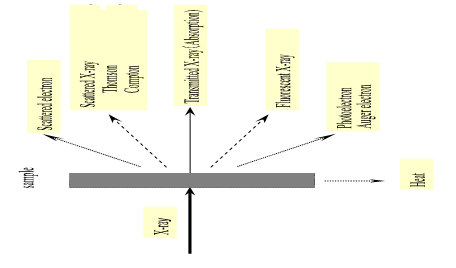

Therefore, when X-rays pass through the matter a number of processes may occur: absorption, scatter, and fluorescence (Fig. 2). X-rays are electromagnetic radiation and can be manifested in two forms, as characteristic and continuous radiation. Charles Glover Barkla proved indirectly in 1906 that the radiation emitted from a sample consists of several spectra of different wavelengths that named K and L spectra. Barkla was awarded the Nobel Prize in physics in 1917 “for his discovery of the characteristics Röntgen radiation of the elements”, as stated by the Nobel Committee. An inner electron may be ejected when a sample is bombarded with high-energy particles, which entails the transition from states of high to low energy of the orbital electrons with the subsequent production of the characteristic radiation (Jenkins, 2000). High-energy electrons approaching the electronic clouds surrounding the nucleus undergo a deceleration, leading to continuous (the continuum or Bremsstrahlung) radiation. The detectability of small peaks by continuous radiation is limited due to the presence of background.

The basis of X-ray radiography is absorption; the heavier elements (high atomic number, Z) weaken the beam to a greater extent than the lighter ones (low Z). X-ray absorption is used (Robinson, 2005) in the nondestructive evaluation of flaws in objects (voids or internal cracks in metals, cavities in teeth, broken bones in humans…), a technique called radiography or X-ray fluoroscopy. This same technique is used to perform security screening of baggage at airports. A computerized version of radiography, computed tomography (CT) scanning or computed axial tomography (CAT) scanning, provides a powerful, high-resolution medical diagnostic tool (of certain disorders in their early stages) by giving a 3D cross-sectional image of body tissues on less than 30 minutes. X-rays damage living tissues, a property which find use in radiotherapy, where malignant growths, which are not able to be removed by surgery, are destroyed in situ, using X-ray beams (Robinson, 2005; Whiston, 1987).

Diffraction patterns obtained through the scattering of X-rays by many solid materials are a special feature of a compound, which is closely related to the atoms’ molecular arrangement, being used to study their crystalline structures, composition, particle size, decomposition (evidence of), polymorphism, preferred orientation, or disorders (Whiston, 1987, p. 2). In this case, the wavelength of the X-rays does not vary, and a diffraction figure is only formed if certain geometric conditions occur, expressed by the law of Bragg or in the conditions of Laue. X-rays wavelengths are comparable to atomic spacing, in this way proving to be a powerful tool for ascertaining the atomic structure of matter (and atoms). This serves as the basis of X-ray diffraction analysis; qualitative identification of crystalline materials is readily made from a measurement of the angles of diffraction. X-ray diffraction also serves as a mean of isolating X-rays of a particular wavelength in an X-ray spectrometer. In 1912, German Max von Laue (together with M. Friedrich and P. Knipping) working with crystalline copper sulphate, made the fundamental discovery of X-ray diffraction (Forman, 1969), a powerful mean of materials characterization. Meanwhile, an alternative method (Eckert, 2012) to confirm the discovery through the interpretation of diffraction as a reflection on selected net planes in the crystal according to the equation [math]2d\sin \theta =n\lambda [/math] was developed by William Henry Bragg and William Lawrence Bragg in England (d is the distance between planes in the crystal, [math]\lambda[/math]the wavelength of the incident beam and the integer n the order of the diffraction pattern). Within about a year it became clear (Jenkins, 1984) that two new sciences, X-ray crystallography, and X-ray spectroscopy, had emerged. Max von Laue was awarded the Nobel Prize in 1914 “for his discovery of the diffraction of X-rays by crystals” and the Braggs received it one year later “for their services in the analysis of crystal structure by means of X-rays” (Thomas, 2012).

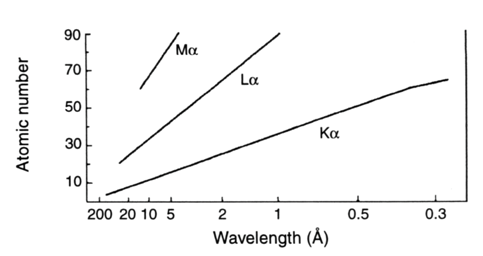

Fluorescence occurs when energetic radiation ejects an inner shell electron creating vacancies in the specimen. Electrons from the outer shells fill then these vacancies. As a consequence, a fluorescent radiation characteristic of the elements that make up the specimen is emitted at specific X-ray wavelengths. XRF spectroscopy has as an object the isolation and measurement of the set of wavelengths that follows the excitation by the X-ray primary beam. Subsequent these vacancies are filling by electrons from the outer shells. The principle is known since 1913 when Henry G.J. Moseley (University of Manchester, and Oxford) found the relation between [math]Z[/math], and [math]\lambda[/math], of the characteristics X-ray emitted. After recording the X-ray spectra of numerous elements, he found that the frequency of emission lines is a function of the Z squared, [math]\nu =c/\lambda =a\left ( Z-\sigma \right )^{2}[/math], where [math]a[/math] and [math]\sigma[/math] are constants depending on the spectral series of the given emission line.

Svante August Arrhenius, the Nobel Laureate in Chemistry for 1903 and one of the most influential members of the Nobel Committees for Physics and Chemistry (Crawford, 1984) nominated Moseley in 1915 for the Chemistry Prize. However, Moseley was killed (August 1915) in action as telecommunications officer at the age of 27 in the Gallipoli campaign during World War I (Margaritondo and Ramachandra, 2015). The impact of Moseley’s law on chemistry was crucial, playing a key role (Sarton, 1927) in the numbering of chemical elements, helping to explain a few atomic weights inversions in the periodic table (Ar-K, Cu-Zn and Te-I), giving rise to the atomic number term, and helping to predict and find six new elements in the next twenty years (Tc, Hf, Re, At, Fr and Pm).

Moseley built the early X-ray spectrometer, based on a cold cathode tube where the air within the tube provided the electrons serving the analyte as the tube target (Bounakhla and Tahri, n.d.). Using electrons to create X-rays is not efficient because about 99% of the energy is lost as heat. Figure 3 shows a plaque commemorative of Moseley’s research work, erected by the Royal Society on the Clarendon Laboratory at Oxford. The method by which the inner vacancy is created in an orbital's an aspect of X-ray fluorescence spectroscopy that has an extreme importance, e.g. the sample may be bombarded with either high energy X-rays or with high-energy electrons and protons. An incident photon beam experiences a photon absorption interaction with the specimen (i.e. sample taken), while electron and proton beams primarily experience a Coulomb interaction with the specimen (Bounakhla and Tahri, n.d.).

Given the existence of a simple relationship between [math]Z, \lambda[/math], or energy [math]E[/math], of a characteristic X-ray photon, isolation of individual characteristic lines leads to an element distinctive identification. Despite the vast history of this technique, the last 50 years or so have been crucial for its routine application of elemental analysis. Complications associated with experimental procedures and preparations remained for a long time. The broad analytical applications of the method were possible (Muller, 1972) by the progress in the indirect excitation of the spectra by the white radiation of an X-ray tube, and the recording of the spectra by counters. A wide range of process instrumentation has been developed in this expanding field to include probes for analysing millimeter and micrometer-size areas, portable analyzers using radioisotopes to excite X-rays, and ion accelerators for measuring surface concentration and trace elements.

Some of the fundamental laws of physics of interest concerned with X-rays are shown in Table 1.

| TABLE 1. Laws of physics of interest in X-rays (Anzelmo et al., 2013a). | |

|---|---|

| Duane Hunt law, 1915 | [math]\lambda_{min}=12.4/kV[/math] |

| Moseley’s law, 1913 | [math]\frac{c}{\lambda }=a\left ( Z-\sigma \right)^{2}[/math] |

| Bouguer-Lambert-Beer, 1729, 1760, 1852 | [math]I=I_{0}\exp \left ( -\mu \rho \tau \right )[/math] |

| Relationship between atomic number, amperage, and voltage | [math]I=1.4\times 10^{-9}iZV^{2}[/math] |

The modern XRF spectrometers can make use (Jenkins, 200b) of either a single crystal isolating narrow wavelengths thanks to its diffraction power, i.e. wavelength-dispersive spectrometry (WDXRF); or a detector (proportional) isolating narrow energy; i.e. energy-dispersive spectrometry (EDXRF). About 80% of actual spectrometers work in the WD mode with analysing crystals whereas only 20% run in the ED mode, mostly Si(Li) detectors, and lately with Si-drift detectors (Klockenkämper and von Bohlen, 2015). Friedman and Birk first described the prototype of the first commercial WDXRF instrument in 1948. Since then, XRF is one of the most widely applied techniques for quantitative and qualitative elemental analysis. An XRF (small scale) device was sent on the Apollo 15 and 16 NASA missions in the early 1970’s, to study the surface rocks of the moon in situ. This analytical technique is extensively used in industrial quality control due to its character as a fast quasi-nondestructive. High-resolution varieties, e.g. microXRF (μXRF) have been developed recently to achieve (Busch, 2015) extremely fine spatial resolution, being of worth in space exploration (it has been used on Mars), in art conservation (Cotte and Susini, 2011), and other scientific disciplines.

Among the general techniques currently used in X-ray methods are (Palmer, 2011) X-ray powder diffraction (XRD) and WDXRF and EDXRF, and other most sophisticated techniques, e.g. total reflectance XRF (TXRF), proton-induced X-ray emission (PIXE), extended X-ray absorption fine structure (EXAFS), and X-ray absorption near edge fine structure (XANES). Using the EDXRF non-destructive multielement analysis from sodium to uranium at ppm levels may be achieved, whereas application of WDXRF leads to an effective determination of low-Z elements down to even Be (note that not all equipment are able to determine elements with Z<10). Mapping (element distribution images) may be obtained scanning the beam in a television-like raster, and displaying then the intensity of a selected X-ray line (Reed et al., 1995). Electrons collected from the sample produce images revealing surface topography or mean atomic number differences, depending on the selected mode (Tsuji et al., 2015).

TXRF is commonly used for trace and microanalysis, as well as for surface analysis. This technique differs fundamentally (Klockenkämper et al., 1992; Klockenkämper and von Bohlen, 2015) from classical XRF though shows similarities with AAS (atomic absorption spectroscopy) and ICP-AES and ICP-MS (inductively coupled plasma techniques with atomic absorption spectroscopy and mass spectrometry, respectively) used in trace element analysis, and with XPS (X-ray photoelectron spectroscopy, RBS (Rutherford backscattering spectroscopy), and SIMS (secondary ion mass spectrometry) for surface analysis. TXRF uses the principle of total external reflection to restrict the penetration of the primary beam (Klockenkämper et al., 1992; Klockenkämper and von Bohlen, 2015) into the specimen substrate. This technique allows an improvement in the detection limit of the system to the sub ppm/ppb level, thanks to the substantial reduction of scattered background. The formation of standing waves above surfaces and within the near-surface layers is the basis of the total external reflection (Klockenkämper and von Bohlen, 2015, p. 15), which results in a sensitivity surface of a few nanometers.

2 X-rays Production Process

The theory established by Bohr in the early 1900’s is enough to explain the nature of the processes involved in XRF, although quantum theory allows a deeper understanding.

2.1 Atomic Structure: Energy Levels in Atoms

According to the classical (Rutherford-Bohr) model, atoms are composed of a positive nucleus with charged protons and non-charged neutrons, and electrons orbiting around it (Reed, 1995). The number of orbital electrons coincides with the protons of the nucleus (equals to Z) when the atom is in its normal state. At determined distances from the nucleus, the electrons spin in shells, and the valence electrons are located in the outer shell. These shells are known as K, L, M, N, O, P, and Q; the K shell being nearest to the nucleus. Historical connotations are associated with the use of the letters that designate the lower shells (Robinson, 2005); K and L come from the German words Kurz, and Lang, which mean short and long, respectively. The K, L, M, etc. line series nomenclature is due to Barkla, and still is in use today. Each shell represents an energy level, composed of different sub-levels. Electrons take on discrete (quantized) energy. The K shell has the lowest energy and the Q shell the highest. However, note that the most tightly bounded are inner shell electrons, which are those that remove from the atom with more difficulty; i.e. the largest energy difference between any two shells is between the K and L shells; the smallest difference is between the outermost shells. Highest potential energy correlates with lowest binding energy.

The different shells correspond to the different principal quantum numbers of the possible quantum states. The principal quantum number, n, has integral values of 1 (K shell), 2 (L shell), 3 (M shell), etc. The angular quantum number, l, may adopt all values from (n-1) to 0. The magnetic quantum number, m, may adopt values of + l to – l (0 included), i.e. 2 l + 1 values in total. The spin quantum number, s, may adopt two values -½ and +½. The total momentum J of an electron is equal to the vector sum of (l+ s). The Pauli exclusion principle governs the inner shell populations, i.e. one electron is characterized by a unique set of quantum numbers.

The L shell is subdivided into three shells [math](L_{1}, L_{2} \; and \; L_{3})[/math] having a different quantum configuration, but very similar energies (Reed, 1995). The number of sub-shell of shell M is five, and seven is that of N., being K shell unitary. The maximum number of electrons (population) of a shell is given for the number of possible states having a given n, the relevant principal quantum number (Table 2). Thus, shells hold only a certain number of electrons; i.e. the maximum population of electrons to full the K, L, M and N shell, are 2, 8, 18 and 32, respectively.

TABLE 2. Number of shells, subshells and electrons.

| [math]N^{\circ}[/math] shells n | [math]N^{\circ}[/math] subshells 2n-1 | [math]N^{\circ}[/math] electrons 2[math]\mathbf{n^{2}}[/math] |

|---|---|---|

| 1 | 1 | 2 |

| 2 | 3 | 8 |

| 3 | 5 | 18 |

| 4 | 7 | 32 |

2.2 Origin of Characteristics X-rays

Atoms can be excited to generate X-rays by different means:

i) Sample may be directly bombarded with high-energy electrons (direct emission analysis, electron probe microanalysis, and Auger emission spectroscopy).

ii) Sample may be irradiated with high-energy X rays having shorter [math]\lambda[/math] than specimen elements (i.e. X-ray fluorescence analysis).

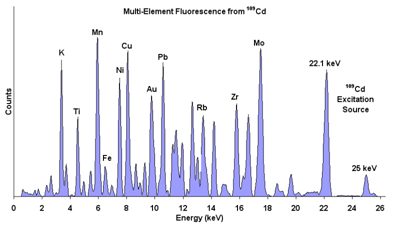

iii) Sample may be exposed to a radioactive source (Fe[math]_{55}[/math], Cm[math]_{244}[/math], Cd[math]_{109}[/math], Am[math]_{241}[/math], Co[math]_{57}[/math]) having sufficient long periods which generate very high energy X-rays(also called [math]\gamma[/math]- rays) in its decay process. Its intensity is some orders of magnitude inferior to that of X-ray tubes not requiring an elaborate power supply, and allowing portable instruments of reduced dimensions, weight and cost (mobile EDXRF systems) to be used. They are used in field, on line and even extraterrestrial applications (Streli et al., 2017). A permit is usually required for the use of these sources, which entail transport, storage and maintenance problems because they are emitting in a continuous way, unlike other conventional sources.

iv) Synchrotron radioactive source (Robinson, 2005; Sauvage-Simkin, 2011) may be used. However, synchrotron accelerators are accessible at only a few locations around the world (Variankaval, 2005), sharing their service with lots of clientele. The X-ray beam (focused by an optic) can be very small and intensive, affording atomic information on the submicrometer scale. Its intensity is some orders higher (6-12) that from an X-ray tube, and its component is linearly polarized and spread only in the plane (of the orbit) of the synchrotron ring (Dolenko et al., 2017; Janssens, 2004). A high X-ray primary beam intensity combined with a low spectral background can obtain detection limits of down to the ppm level.

v) Alpha particles or other heavy particles bombarding a sample (PIXE); this requiring an appropriate accelerator.

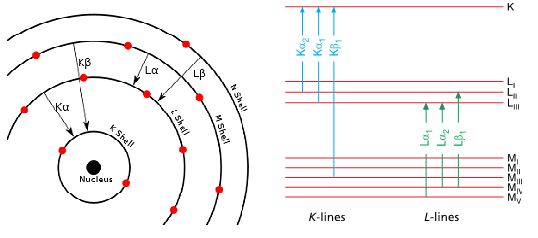

X-ray methods imply exciting an atom by expelling an electron from an inner energy level (Patnaik, 2004), usually from K or L levels (Fig. 4). The [math]\alpha, \: \beta, \: \gamma,[/math] etc. subscripts are used to identify the original electronic level of the electron that occupies the empty space. Thus, a transition of the nearest electronic level is indicated by the letter [math]\alpha[/math], the next one with the [math]\beta[/math], etc. The [math]K\alpha[/math] transitions are approximately six times more likely to occur (thus more intense) than the corresponding [math]K\alpha[/math] transition. Sometimes to identify the particular sub-level or spin state at the main level from which the transition originates, additional numerical subscripts are used ([math]K\alpha_{1},K\beta _{1}[/math], etc.). When an X-ray or a fast-moving electron collides with an atom, the atom may absorb its energy. If the X-ray or electron has sufficient energy, it knocks an electron out of one of the atom’s inner shells (e.g., the K shell), resulting in the removal of this (photo)electron, the atom becoming ionized. The energy of the emitted photon is equal to the differences of energy between the states, initial and final, of the transferred electron. Then, the energy acquired in the excitation process is re-emitted totally or partially, and an electron from a higher-energy shell (e.g., the L-shell) falls almost instantaneously, in 10[math]^{-16}[/math]s, into the position vacated by the dislodged inner electron an X-ray photon being emitted in this process.

The initial vacancy is thus immediately filled by an electron from a higher energy shell, creating a vacancy in that shell that is, in turn, filled by an electron from a yet higher shell. Thus, by a series of transitions, [math]L\rightarrow K,\: M\rightarrow L,\: N\rightarrow M[/math], each new vacancy is filled until the excited atom returns to its ground state. Theoretically this process can go until the outermost orbital is reached. However, in practice it stops rather quickly. The reason for this is that the efficiency of X–ray production is quite low. Only a minor fraction (about 1%) of an electron beam produces X rays. The remaining major percentage of the energy is released as heat, requiring special water-cooling of the target. Quantum mechanical dipole selection rules govern transitions ([math]\Delta n\gt 0,\: \Delta l=\pm 1,\: \Delta J=\pm 1\: or\: 0[/math]) leading to the most intense lines. Some of the transitions are allowed whereas others are forbidden, like in all forms of spectroscopy. Thus, K level vacancies only allows the transitions [math]p\rightarrow s[/math] yielding two lines ([math]L_{2}\rightarrow K[/math] and [math]L_{3}\rightarrow K[/math]) for each main level change (Fig. 5). Similar rules follow L level vacancies yielding to L series lines. The number of lines is now greater because the selection rules allow the transitions [math]p\rightarrow s,\:s\rightarrow p [/math] and [math]d\rightarrow p[/math]. On the basis of the suitable number of transition levels, the transition groups can be easily composed.

2.3 Nomenclature

As we have previously indicated, each electronic transition (apart from radiationless transitions) results in the emission of a characteristic X-ray spectral line whose energy [math]h\nu[/math] is equal to the difference between the binding energies of the two electrons involved in the transition. Every element has its characteristic K, L and M series. Thus, H and He (hydrogen and helium, respectively) do not have XRF spectra since they lack an electron at level L. Light elements from beryllium to fluorine give rise to only a single transition of type [math]K_{\alpha}[/math]. Mid-range elements can emit both K and L series while the heavy elements produce K, L and M series. Thus, the spectra get increasingly complex when we go towards heavier elements. When dealing with heavy atoms, cascade electronic rearrangements are observed, unlike to lighter elements whose electrons are distributed over a smaller number of ground states. In practical XRF, we select the main lines of K and L series to measure an element although there may be other lines present.

The X-ray spectral lines are designated by the symbols such as Ni [math]K_{\alpha _{1}}[/math], Fe [math]K_{\beta _{2}}[/math], Sn [math]L_{\alpha _{2}}[/math], and U [math]L_{\alpha _{1}}[/math]. The symbol of an X-ray line represents the chemical element (Ni, Fe, Sn and U); the notations K, L or M indicate that the lines originate by the initial removal of an electron from the K, L, or M shell, respectively; a given line in the series is designated by the Greek letter [math]\alpha ,\: \beta[/math], etc. (representing the subshell of the outer electron involved in the transition), plus a numerical subscript. This numerical subscript indicates the relative strength of each line in a particular series – for example, [math]K_{\alpha _{1}}[/math] is more intense than [math]K_{\alpha _{2}}[/math].

The use of a Greek letter and numerical subscript to identify an X-ray emission line is traditionally called the Siegbahn notation, developed years ago by Manne Georg Siegbahn, who was awarded the Nobel Prize in Physics in 1924 “for his discoveries and research in the field of X-ray spectroscopy”. His son Kay Siegbahn also later received the Nobel Prize in 1981 for the discovery of X-ray photoelectron spectroscopy.There are several nomenclature systems for atomic shells, depending on the energy levels (K, L[math]_{1}[/math], L[math]_{2}[/math], M[math]_{1}[/math]), electronic configuration (1s, 2p[math]_{3/2}[/math]) or quantum numbers [2, 0, 1⁄2]. Not all X-ray lines have a Siegbahn designation, so the IUPAC established a new identification system for X-ray lines (Jenkins et al., 1991): a line in the spectra is denoted by the element and the shell where the initial hole was; the shell where the electron comes from that fill this hole follows then (Table 3). Although the notation established by IUPAC is much more rational, it is not yet in common use.

Table 3. Correspondence between the Siegbahn and IUPAC notations.

| Siegbahn | IUPAC | Siegbahn | IUPAC |

|---|---|---|---|

| K[math]\alpha_{1}[/math] | K-L[math]_{3}[/math] | L[math]\alpha_{1}[/math] | L[math]_{3}[/math]-M[math]_{5}[/math] |

| K[math]\alpha_{2}[/math] | K-L[math]_{2}[/math] | L[math]\alpha_{2}[/math] | L[math]_{3}[/math]-M[math]_{4}[/math] |

| K[math]\beta_{1}[/math] | K-M[math]_{3}[/math] | L[math]\beta_{1}[/math] | L[math]_{2}[/math]-M[math]_{4}[/math] |

| K[math]\beta_{2}[/math] | K-N[math]_{3}[/math] | L[math]\beta_{2}[/math] | L[math]_{3}[/math]-M[math]_{5}[/math] |

2.4 Absorption and Fluorescence

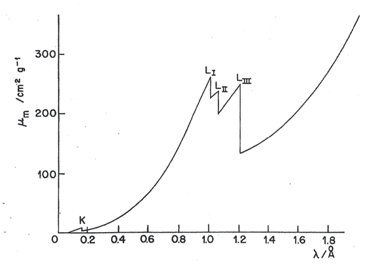

Atoms and molecules can absorb X-rays. The absorption spectrum of an element (like is emission spectrum) is simple, consisting of a few well-defined absorption peaks, the wavelengths of the absorption maxima being characteristics of the element and largely independent of its chemical state. Fig. 6 shows a typical curve of mass absorption coefficient against the X-ray wavelength for tungsten (W); absorption is increasing as wavelength increases. Long wavelengths imply less energy and then less penetrating power, and in consequence, they are absorbed in a more readily way. We may consider the mass absorption coefficient as a measure of the probability of incident radiation to be absorbed, which increases with the wavelength until reaching the absorption limit, where a sudden drop occurs. At certain specific values of wavelengths (energies) that are characteristic of an element, known as wavelength (absorption) edges, there is an abrupt increase (discontinuity) in the mass absorption coefficient (i.e. amount of energy absorbed). This wavelength (energy) corresponds to the ejection of an electron from the element. As the wavelength (absorption) edge is characteristic to the element, the wavelength (absorption) energy can be used with the aim of identifying elements.

The K absorption edge of W occurs at 0.178Å ; X-rays having [math]\lambda \gt [/math] 0.178Å displace K electrons form W atoms, emitting characteristic X-rays in a phenomenon known as X-ray fluorescence, as previously indicated. The energy of X-rays with [math]\lambda \gt [/math] 0.178Å is insufficient to carry out the displacement. Three closely spaced L absorption edges ([math]L_{I},\: L_{II},\: L_{III}[/math]) may also be seen in Fig. 6, marking the wavelength of the incident X-ray beam having (its quanta) sufficient energy to displace L electrons from the atom. The electrons L are more weakly attached to the nucleus and therefore are started at wavelengths longer than the electrons K. In addition, the L-electrons have three slightly different energetic levels giving rise to three close peaks between them. Groups of M and N edges might even appear at longer wavelengths.

The wavelengths of the absorption edges and of the corresponding emission lines do not quite coincide. This is because the energy required to dislodge an electron from an atom (the absorption edge energy) is not quite the same as the energy released when an electron from an outer shell (emitted X-ray energy) replaces the dislodged electron. The amount of energy requited to displace the electron must dislodge it from its orbital and remove it completely from the atom. This is more than the energy released by an electron in an atom that is falling from one energy level to another.

The mass absorption coefficient does not decrease to the zero value after an absorption edge for two reasons: i) there are other electrons that are more weakly bonded and can interact with the X-rays, and ii) in addition to the electron expulsion, dispersion of X-rays by electron contributes to the absorbance. The importance of dispersion increases at low wavelengths ([math]\alpha[/math] decreases) and for low atomic numbers (Z minor). But except when working with light elements (such as carbon, nitrogen, and oxygen), the contribution of dispersion to the total mass absorption coefficient is very little.

Between the limits of absorption, the mass absorption coefficient can be related to the wavelength [math]\lambda[/math] and the atomic number Z by the following approximate empirical equation

[math]\mu \approx \frac{CN}{A}Z^{4}\lambda ^{3}\tag{1}[/math]

where C is a proportionality constant; N is the Avogadro number, and A is the atomic weight of the absorbent element. This equation is more accurate as Z and [math]\lambda[/math] increases (dispersion decreases), assuming that the photoelectric absorption process is the only important variable. Note that as the wavelength increases, the slope between the absorption peaks in a logarithmic representation would reach the value of three, according to Eq. 1.

From an analytical point of view, these principles can be used (Olsen, 1975) in different ways. Three of them can be called X-ray absorptiometry because they are based on Beer’s law of absorption. A fourth method is based on measuring the X-rays of longer wavelengths emitted after irradiating the sample with primary X-rays (fluorescence). All these methods can be explained with reference to the mass absorption curve of the figure.

To irradiate the sample, the following methods may be used:

i) Monochromatic X-rays, preferably of a wavelength such that it corresponds to the short-wavelength zone of an absorption discontinuity. This method is not very specific since most of the elements present absorb in a greater or lesser degree, and the sensitivity is also relatively low;

ii Sequentially monochromatic X-rays of different wavelengths of a range around the absorption limit of the problem element. This absorption limit is located by extrapolation and is used to identify the present element. This is a specific method for a given element, and although relatively insensitive and requires some manipulation of the data to obtain the results, it has been used successfully in routine analyses, especially in the determination of chlorine, sulphur and bromine in hydrocarbons.

iii Polychromatic X-ray bundles. It allows simple and resistant photometers to be used. However, although the sensitivity may be relatively high, the method is very unspecific;

iv The fourth method using these principles for analytical purposes is based on measuring the X-rays emitted by a sample, rather than measuring the absorption of the primary X-rays used. In this case, a primary X-ray polychromatic beam is used to irradiate the sample. Of these, those having a wavelength shorter than the peak to be used produce the photoelectric ejection of an electron from the bombarded atom, the subsequent rearrangement of electrons, and emission by the characteristic secondary (fluorescent) X-ray specimen, which are those which are measured. This method, called X-ray fluorescence spectroscopy, is very specific and can be used in an elemental qualitative analysis. It is quite sensitive although its specificity is its major advantage.

2.5 Continuous Radiation Spectra: Short Wavelength Limit (SWL)

Taking into account the relationship [math]E=h\nu =h\, c/\lambda [/math], connecting the energy E and wavelength [math]\lambda[/math], where h is the Planck constant, [math]\nu[/math] the frequency of the radiation and c the speed of light, either the frequency or the energy may be used to characterize the radiation emitted. The relationship between the energy E and the voltage applied V is given by E = eV, where e is the electron charge. Therefore (Robinson, 2005) when all the energy of the electron is converted to X radiation (instantaneous deceleration to zero kinetic energy in a simple collision), the wavelength of the radiation is a minimum, Duane-Hunt law (and therefore the highest energy)

[math]\lambda _{min}=\frac{hc}{eV}=\frac{\left ( 6.626\, 10^{-34}\, Js \right )\left ( 3.0\, 10^{8}\, m \right )\left ( 10^{10}\, A/M \right )}{\left ( 1.60\, 10^{-19}C \right )V}=12,400/V\tag{2}[/math]

[math]E(keV)=\frac{12.4}{\lambda Å }\tag{3}[/math]

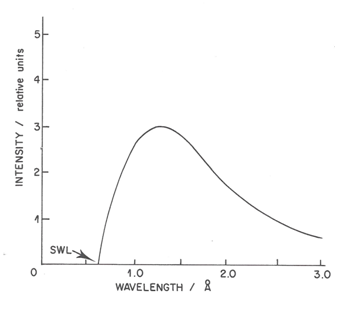

The maximum intensity of the continuous radiation wavelength is approximately 1.5 times the minimum wavelength.

Equation (2) provides a direct means for the highly accurate determination of Planck's constant. The continuous radiation spectrum called “Bremsstrahlung” (Brouwer, 2010) (“Brems“ is German for decelerate; “Strahlung“ for radiation) from a solid metal, therefore, has a well-defined short wavelength limit (SWL). The limit is a function of the accelerating voltage, but not of the solid metal. The same [math]\lambda_{min}[/math] would be obtained by bombardment of lead or tungsten or rhodium at a given accelerating voltage.

The continuous radiation results from the collision of electrons with the atoms of the solid. The electron is losing energy in each collision and decreases its speed producing an X-ray photon, with energy equal to the difference of kinetic energy resulting from the collision. Each electron generally undergoes a series of collisions with each collision resulting in a photon of slightly different energy. The results of these many collisions are the emission of a continuum of X-rays over a wide range. According to classical electromagnetic theory, the process of acceleration of charged particles is accompanied by an emission of radiation, which is a simple explanation of the continuous emission of X-rays.

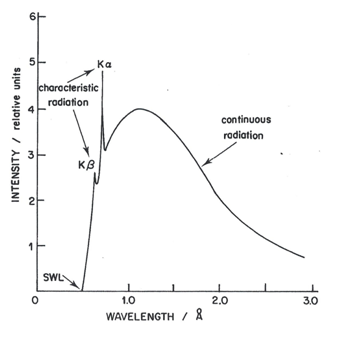

Figure 7 shows the continuous spectrum formed by an X-ray tube containing a molybdenum (Mo) target (anode or anticathode) operating at 20 kV (molybdenum tube). As the accelerating voltage increases above a critical value (characteristic for each element) very narrow emission sharp peaks superimpose on the continuous background. Figure 7 top shows the spectrum produced by the tube operating at 25 kV.The characteristic radiation of the X-ray tube is spread in space isotropically, whereas its continuous radiation has maximal intensity in a plane perpendicular to the trajectory of electrons bombarding the target (Dolenko et al., 2017).

The continuous spectrum is a feature of great utility in an X-ray tube and provides a versatile source of these rays to radiate different elements. The intensity or total power of the emission spectrum of an X-ray tube (integral of the intensity across the spectrum), I, depends on the applied electric power iV in watts, where i is the current in amps and V is the voltage in volts, and of the efficiency in the X-rays production. In practice, the efficiency can only be evaluated empirically, nevertheless, the following equation can be used to estimate the total intensity

[math]I=\left ( 1.4\, 10^{-9} \right )iZV^{2}\tag{4}[/math]

where Z is the atomic number of the bombarded element that is used in the X-ray tube. The equation is not fulfilled by decreasing V, but in any case, it reveals two facts that must be taken into account in the production of X-rays with a bombardment of electrons. It is obvious that this method of production is very inefficient since less than 1% of the energy of the electrons is present in the X-ray beam. The rest of the energy is transformed into heat, so it is necessary to take special precautions to cool the anode whenever necessary. The greater the electrical power applied, the greater the problem of heating.

It is also observed in Eqn. (4) that the intensity depends on the atomic number of the anode used as a target in the cathode ray tube. In fact, in practice, the spectral distribution in the continuum is relatively constant when changing the element (note that the minimum wavelength is independent of Z). However, the absolute intensity is greater for the higher atomic number elements. Tungsten (K[math]\alpha[/math] line at [math]\lambda[/math]= 0.021 nm; E=59 keV) is the element most commonly used in X-ray tubes, because its atomic number is high and its high melting point allows the use of high currents in the tube. If we work at 50 kV with this anticathode, we obtain X-rays that are able to excite the radiation K of all the elements of the periodic table to the cerium (Z = 58). However, the power required from the generator tends to be decreased nowadays, because of the extreme increase in the sensitivity of X-ray detectors. With rhodium as the X-ray tube target we get: K[math]\alpha[/math] line at [math]\lambda[/math]=0.061 nm; E=20.3 keV. Low power (less than 500 mW) miniature X-ray generators have been developed for portable instruments. Laser impact from a pyrolectric (tantalum) crystal yields the electrons required to generate the X-rays in the Cu target material (Rouessac and Rouessac, 2007).

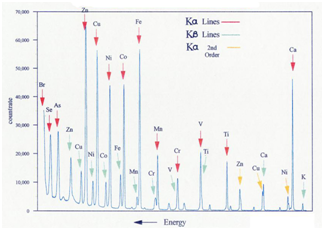

2.6 Characteristic Spectra

The number of lines of an element, observed in practice, depends on a series of factors such as Z, excitation conditions, and range of [math]\lambda[/math] used. Each element has a different arrangement of electrons about its nucleus and thus a different set of energies, then X-rays of characteristic wavelengths and energies that are emitted by each element. The set of lines emitted of each element is contained in its code bar or fingerprint. When the sample consists of many different atoms, each produces a series of wavelengths, all contributing to the total X-ray emission spectrum. Conventional commercial spectrometers cover the K, L and M series, which carry out most of the analytical work. In the higher series, a much larger number of lines are available. The secondary X-ray radiation is much weaker than the primary X-ray beam, and for lighter elements (up to phosphorus, Z=15) is of low E (long [math]\lambda[/math]). So, its power of penetration is low, the beam is drastically attenuated in passing through the air for any distance, and also being absorbed by the detector windows and the sample coating. Consequently, the path of the sample to the detector should keep under a high vacuum (for high throughput analysis). This implies that most of the working parts of the instrument, in practice, must be situated in a large vacuum chamber.

The wavelengths of this emitted X-ray (characteristic lines) and intensities associated depend only on the element being bombarded, because the inner electrons do not take part in bonding. Therefore, the lines are (essentially) independent of oxidation state, bonding, and physical state, making the use of the characteristic lines an elemental analysis technique. Table 4 shows wavelength data for the emission of a few elements. No molecular information is obtained from these lines. Because there are a limited number of possible inner shell transitions, the X-ray spectrum is much simpler than the complex optical spectrum that results from the removal or transition of valence electrons. Furthermore, XRF does not requires destructive dissolution and/or atomization by a flame, arc, spark or plasma, unlike what usually occurs with optical emission (and absorption) methods. Although most of the fluorescence lines observed in the X-ray spectrum are normal, some may appear that do not fit first with the selection rules. No sharp energy distinction between orbitals appear at outer levels, thus arising to forbidden lines. Dual (and multiple) ionization leads to satellite lines. However, both forbidden transitions and satellite lines lack analytical significance, because their intensity is some orders of magnitude inferior to that of the main lines. Nevertheless, they made perturb the interpretation of qualitative spectra and cause some difficulties in trace element analysis. The energy required to extract the K-level electrons from the heaviest elements is too high for the continuous tungsten spectrum source, but this radiation is relatively efficient in the excitation of the L and M spectra of these elements. Tungsten X-ray tubes have been manufactured that can work at 100 kV, allowing K-spectra of heavier elements, up to gold (Z = 79). This fact represents an important advantage, since the K spectra are much simpler and more intense than the L or M. The emission lines of the K series, for example, are about ten times more intense than those of the series L.

In some cases, other factors are important for the choice of cathode ray tube material.For example, if tungsten is to be analyzed by XRF, it is convenient to use a tube with a different element, e.g. molybdenum, as the anticathode, since part of the primary radiation of tungsten can be dispersed by the sample and reach the detector, interfering in the measurement of the fluorescent radiation of tungsten. Another factor to be considered in the choice of the anticathode is its calorific effect, which determines the thickness of the tube window. In general, thin windows with low atomic number anodes can be used, these windows have advantages when using long wavelength X-rays, for example in the analysis of light elements.

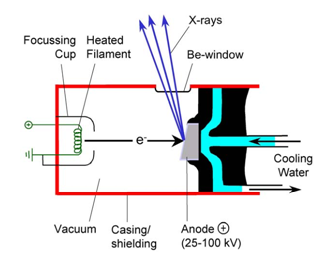

The cathode is heated by current flowing through a filament and the high voltage towards the anode accelerates the emitted electrons. The collision of the electrons with the anode produces heat energy and X-rays, a high proportion of which passes through the window. The heat produced, in great quantity, must be dissipated, which is achieved, in general, by circulating water through the anode. However, the power required from the generator tends to be decreased nowadays because of the extreme increase in the sensitivity of X-ray detectors. Modern X-ray tubes have been designated to operate at lower voltages and do not require water cooling of the anode (Robinson, 2005).

TABLE 4. Wavelengths in Angstroms of the more intense lines for some typical elements (Skoog, Holler and Crouch, 2017)

| Element | Atomic Number | K Series

[math]\alpha _{1}[/math] |

K Series

[math]\beta_{1}[/math] |

L Series

[math]\alpha _{1}[/math] |

L Series

[math]\beta_{1}[/math] |

|---|---|---|---|---|---|

| Na | 11 | 11.909 | 11.617 | - | - |

| K | 19 | 3.742 | 3.454 | - | - |

| Cr | 24 | 2.290 | 2.085 | 21.714 | 21.323 |

| Rb | 37 | 0.926 | 0.829 | 7.318 | 7.075 |

| Cs | 55 | 0.401 | 0.355 | 2.892 | 2,683 |

| W | 74 | 0.209 | 0.184 | 1.476 | 1.282 |

| U | 92 | 0.126 | 0.111 | 0.911 | 0.720 |

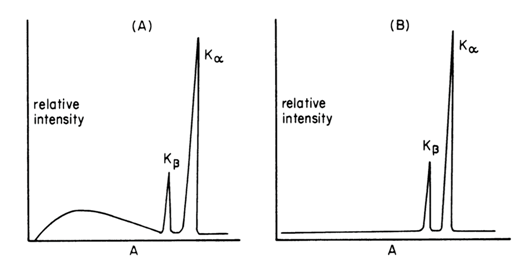

An incident beam of high energy X-rays (the primary beam) may be used to excite the target atoms sufficiently to kick out K electrons. After a short time, the excited ion returns to the ground state, producing a fluorescence spectrum similar to the emission spectrum. However, only the line spectrum appears without the continuous background. Thus, fluorescence spectra show a much greater signal-to-background level and are preferred for analytical work. Thus, in practice, the X-ray spectrum emitted by a given element may consist of a series of characteristic sharp lines (Fig. 8 right) or may be a more complicated spectrum formed by a continuous spectrum of X-rays having very sharp superimposed spectral lines (Fig. 8 left). Whether one or the other spectrum is obtained depends on whether high-energy electrons (Fig. 6 left) or primary X-rays (Fig. 8 right) have been used to bombard the element and expel the internal electron. Of course, the metal used in the target of the first source must have a higher atomic number than chromium to generate fluorescence. The intensity of the secondary source is lower than that a Cr X-ray tube. Loss of intensity, however, is more than offset by the low background from the secondary source in those cases in which monochromatic or nearly monochromatic radiation is required (Robinson, 2014).

2.7 Peaks in the X-rays Spectra

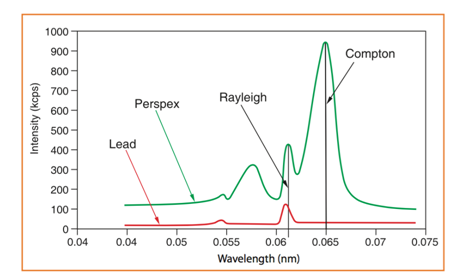

The interpretation of the process has been somewhat simplified, since the atom can lose its excess energy not only by the fluorescence process. When striking a sample with a primary X-ray source, it can be either absorbed or scattered (reflected instead of producing characteristic radiation) through the material. Rayleigh scattering (elastic scattering, without loss of energy) and the Compton effect (release of Compton electrons by inelastic scattering with loss of energy) may also occur (Brouwer, 2010). Samples with light elements (low atomic number specimens) having many loosely bound electrons give rise to the Compton effect and Rayleigh scattering, high and low, respectively. As the atomic number increases (heavier elements) the scatter is reduced, causing the Compton scatter (of greater dispersion and wider spectrum peak) to disappear completely and leave only the Rayleigh scatter. Arthur Holly Compton was awarded the Nobel Prize in Physics in 1927 "for his discovery of the effect that bears his name". Fluorescence and dispersion are dependent on factors such as composition of the material, energy of the X-rays, density and thickness (Bounakhla, nd).

Instead of emitting an X-ray photon, the energy released may knock an electron out of the M shell. This electron is named an Auger electron, and its process formation is the basis of Auger electron spectroscopy (a related method, X-ray photoelectron spectroscopy, is also based on the measurement of the emitted electron). Either X-ray emission or Auger electron ejection occurs for each excited atom, but not both, as they are competitive processes. The number of vacancies in electron levels, which leads to the production of characteristic X-ray photons is, in practice, less than the total number of vacancies created in the excitation process. This is a factor to take into account in determining the absolute number of counts given by an element subject toa set of experimental conditions.

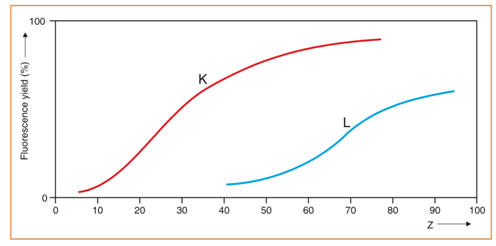

The percentage (fraction) of the excited atoms, emitting X-rays, is named the fluorescent yield (Hubbell et al., 1994; Thomsen, 2007). The fluorescent yield for elements with low atomic numbers is very small and is the reason why the sensitivity of the spectrometric technique is quite poor for elements with very low atomic numbers. If we compare the intensities found for pure barium (Z = 56) and pure aluminum (Z = 13), in equal conditions, the counts given by pure barium are about 50 times higher. The L fluorescent yield is always less than the corresponding K fluorescent yield (Fig. 8) by about a factor of three. No peaks in XRF produce organic elements (i.e. H, C, N, O). Air absorbs low energy X-rays from light elements, as indicated previously, particularly below Ca (Z=20). The detection of light elements requires the use of two different chamber atmospheres a vacuum, for solid and pressed pellets, and helium, for liquid or powdered samples.

Therefore, in addition to elemental peaks (e.g. K & L spectral peaks), we may have other peaks in the spectra: Rayleigh scatter peaks (from target anode in X-ray tube source), Compton scatter peaks (which arise from target element in X ray tube), escape peaks, sum peaks and Bremsstrahlung. Escape peaks are artifact peaks that appear as a consequence of the absorption of some of the energy of a photon by Si atoms in the detector. Prominent at high concentration and lower Z may be reduced by keeping count rates low. When two photons arrive at the same time ([math]K_{\alpha}+K_{\alpha}[/math], [math]K_{\alpha}+K_{\beta}[/math]) gives origin to artefact peaks named sum peaks. Keeping count rates low also reduces this effect. Artifact peaks due to blank media, peaks owing to contaminants in XRF cups, Mylar films, and matrices can also complicate the interpretation of spectra (false positive).

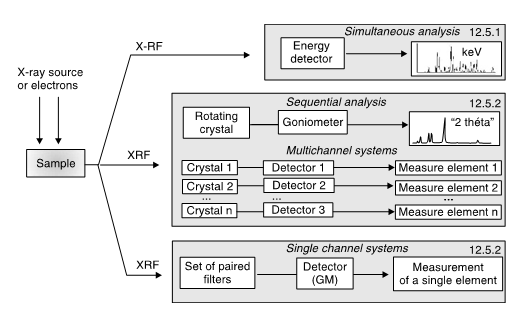

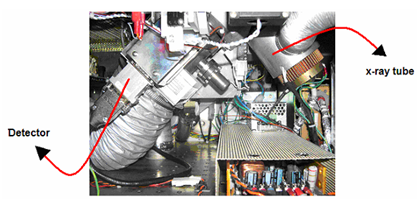

3 XRF Instrument Configurations

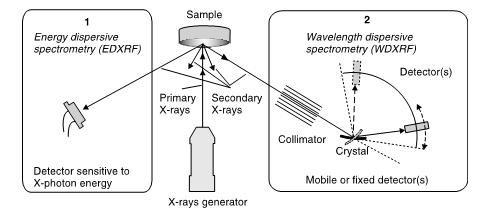

The basic elements of common X-ray spectrometers consist (Anzelmo et al., 2013) in: the primary source unit (where the primary X-ray beam excites the sample), the actual spectrometer itself(where the secondary X-rays emitted are detected),and the electronic measuring device (where the detected radiation is amplified and displayed). These instruments are very sophisticated and somewhat expensive, although the principles on which they are founded are quite simple. The sample might be made the target in an X-ray tube. However, it is more opportune to produce the XRF spectrum from a typical tube (Fig. 12), the most widely used, known as a Coodlige tube, using X-rays of high energy and working under a vacuum ([math]\sim 10^{-4}[/math] Pa, or [math]\sim 10^{-9}[/math] atm). The tube can adopt two geometries: the side window tube and the end window tube (Robinson, 2005; Whiston, 1987). The XRF instruments divide into two main categories (AMC, 1990; AMC, 2006) taking into account the detection system used: wavelength-dispersive (WDXRF), with the use of a monochromator (where the fluorescing radiation is dispersed), and energy-dispersive (EDXRF) detection systems, using a detector capable of determining the energy of counted photons. WDXRF is prevalent among the laboratory spectrometers, and EDXRF in the field of small size portables equipment, with a lower X-ray tube or a radioactive source allowing field measurements.

Normal X-ray tubes used in spectrometers employ acceleration voltages in the range of 25-50 kV, and electron currents of the order of 20-50 mA. In the case of the WDXRF, 3 kW tubes are frequently used, while 50-1000 W tubes are used in EDXRF depending on the excitation mode of the sample (Janssens, 2013; Janssens, 2004).The anode of high-power tubes (> 100 W) is usually water-cooled to prevent a meltdown of the metal block, given the low efficacy of conversion of electric power into X-rays, which is about 1 %, the remaining 99 % dissipating as heat.For power levels of the order of 3 kW rotating anode tubes are used, which have the advantage that only the electrons for a short fraction of time bombard a small area of the surface, the rest of time being used in heat removing. It can thus be operated with commercial tubes up to a total power of 18 kW (Janssens, 2013; Janssens, 2004).Note that the process of cooling is not necessary with modern equipment operating at low power (> 50 W), much lower than that of high power tubes ([math]\geq[/math]1 kW). This reduction is possible thanks to the greater sensitivity of X-ray transducers (Skoog et al., 2017). The cheapest and simplest way of obtaining approximately monochromatic X-rays, when it is necessary, is to filter the continuous spectrum from an X-ray tube. When a monochromator is used, cleaner radiation is achieved, but its cost is about 10,000 times more than that of a thin sliver of metal of the correct thickness.

The energy dispersive methodology was carried out with the purpose to acquire the entire XRF spectrum simultaneously, therefore eliminating the condition to obtain data in parcels. EDXRF is the system of choice when looking for multielement information. The EDXRF method instrumentation is simpler, but it does not provide the same degree of wavelength resolution that is shown by WDXRF spectrometers. WDXRF is best suited for fast accurate determination of only a few elements. Despite the operational and implementation differences, both WDXRF and EDXRF instrumentation are based on the same basic principles. In WDXRF (Fig 13 right),a dispersing device separates X-rays of differing wavelength by deflecting them at different angles proportional to their wavelength. As no proper transparent materials are accessible for making lenses, passing through a series of slits or a collection of long narrow tubes collimates the X-rays.As there are no available prisms, the crystals of many salts disperse light and can be used as excellent monochromators. Between the source and the sample we may place a filter, which help to diminish the intensity lines and background, thus improving the S/N (signal to noise) ratio. Tube lines are absorbed whereas lines coming from the sample are not.

In EDXRF (Fig. 13 left), there is no dispersing device, and a detector (e.g. a solid-state detector) measures and records the energies of each individual detected X-ray photon. The primary irradiative intensity constitutes an important difference between the two, and may differ by a factor of 10 or more, which should be considered when dealing with sensitive materials. Table 1 compiles some characteristics of both the WDXRF and EDXRF systems. For EDXR, the elemental range goes from Na (sodium) to U (uranium). The range for WDXRF is wider, from Be (beryllium) to U (uranium). In terms of concentration, the range oscillates between sub-ppm and 100% levels. The high sensitivity of modern spectrophotometers can detect fingerprints, so precautions must be taken in order not to disturb the analysis (Brouwer, 2010). A comparison of the methodologies for XRF measurements is shown in Table 5.

The EDXRF spectrometer system (Fig. 14), first available in the early 1970s, excites a sample using an X-ray tube, generating characteristic radiation for each element in the sample. A portion of that radiation is directed to a detector, giving output pulses proportional in height to the X-ray photon energy, which are used in conjunction with a pulse height analyzer (multichannel type). Solid state Si(Li) or Si drift detectors are usually used, given their superior energy resolution. The ionization occurs in the detector as the X-ray photons strike, amplifying the electric charge then. Both detector and preamplifier are cooled with liquid nitrogen to minimize electronic noise. The detector serves the purpose of determining the energy of each characteristic X-ray generated (qualitative analysis), and simultaneously the number of X-ray photons emitted per second for each energy (quantitative analysis).

A computer (the first analytical instrument to fully use its potential) containing various algorithms converts the intensity found (number of photons per second) for each element to concentration units (Anzelmo et al., 2013). EDXRF provides unique opportunities for rapid qualitative analysis, of great worth in both forensic analysis (Bailey, 2014) and alloy sorting applications. EDXRF systems of small dimensions are equipped with either a small size and lower X-ray tube, or a radioactive source for field measurements.

The WDXRF system, available since the early 1950s, operates in a similar way, except that an analyzing crystal is inserted between the sample and the detector for the purpose of separating (resolving) the different wavelengths (energies), and then directing those wavelengths to the detector. Usual analyser crystals (alphabetically) include ADP (ammonium dihydrogen phosphate), EDDT (ethylene diamine dextrotartrate), Ge, graphite, InSb, LiF, NaCl, PE (tetrakis-(hydroxymethyl)-methane: penta-erytritol), KAP (potassium hydrogen phthalate), RbAP (rubidium hydrogen phthalate) and TlA (thallium(I) hydrogen phthalate). Analyzing crystals such as KAP, RbAP, ADP, EDDT, PET, NaCl etc. are sensitive to humidity. The surface of the crystals deliquesces if exposed to the air, decreasing the intensities of the reflection of the X-rays, damaging the resolution. Because of this reason, the interior of the spectroscopic chamber must be kept in a vacuum, even when the X-ray spectrometer is out of use. Highly acid or alkaline samples, or any samples which sublime at low temperatures, deteriorate the analyzing crystals and led to lower reflection intensities.

In the detection of lithium (Li) to magnesium (Mg), i.e. in the range of light elements, a additional synthetic multilayer is used. WDXRF instruments are widely used in routineanalysis, production, quality control, and research, when the speed of analysis and analytical precision are mandatory. In these instruments the excitation source is an X-ray tube, available either with one or two scanning goniometers, or with a number of multiple fixed goniometer channels. In the first case, the elemental analysis is carried out sequentially, while in the second elementary simultaneous detection is performed (Fig. 14). In WDXRF, two modes of operation, sequential and simultaneous detection, respectively, are thus possible. In order to record the spectrum, either a linear intensity of a logarithmic scale may be used. In the latter case, very large peaks are not lost, but there is a risk of loss of small peaks.

A very stable high voltage generator plus a sealed X-ray tube with a metallic anode (of Ag, Au, Cr, Mo, Rh or W), called an anticathode, constitutes the primary source of excitation. The generator is able to supply up to about 3 kW of power as a potential of over 60-80 kV (Jenkins, 2000a). WDXRF uses natural crystals and layered synthetic microstructuresas dispersion devices. Detector types range from the gas filled to solid state and even charge-coupled devices (CCD) for XRF. The microprocessors (interface with the human operator) direct and coordinate all of the operations of the spectrometer (Anzelmo, 2013), including capturing the data, processing it, or sending it to a computer for processing, or a network for distribution and storage. An unfiltered beam of primary X-rays irradiates the sample (Janssens, 2013) and a portion of the X-ray fluorescence radiation collimated by the entrance slit of the goniometer is directed onto the surface of the analyzing crystal. The radiation is reflected according to the Bragg equation, passing through the exit collimator to the detector. The diffracted characteristic photons are converted into voltage pulses, which are integrated and finally displayed as a measure of the characteristic line intensity. The major problem related with WDXRF instruments stems from Bragg’s law: it is not possible to measure all wavelengths from a XRF spectrum in a single scan. Therefore, it may be necessary to run multiple spectra when elements in a study differ widely in their atomic numbers.

The low energy X-rays emitted by elements with atomic numbers less than sodium (Z, 11) are easily absorbed by air. Therefore, most X-ray systems operate either under a vacuum or are purged with helium (Robinson, 2005). The entire spectrometer, including the source, sample, optics, and most detectors are within the vacuum/purge chamber. Liquid samples cannot be analyzed under a vacuum, so most systems permit the analyst to switch from a vacuum to a helium purge as needed, usually in less than 2 min.

The great diversity of instruments available (which fit the two main categories previously mentioned) can be classified (Patnaik, 2004) into four basic types: i) simultaneous wavelength-dispersive; ii) sequential wavelength-dispersive; iii) bremsstrahlung source energy-dispersive; iv) secondary target energy-dispersive. Although physically show little physical resemblance, its variation from the analytic point of view lies (Jenkins, 1999) in i) the source used for excitation; ii) the possibility of simultaneous measurement at a given time; (iii) the speed of collecting data; and iv) cost. All the above-mentioned instruments can measure elements of the periodic table from fluoride (Z=9) upwards. They may be equipped with samplers and be automated with the aid of computers, and can reachprecision on the order of a few tenths of one per cent, having sensitivity levels down to the low parts per million.

Recent XRF configurations (AMC, 2008; Bosco, 2013) include handheld spectrometers used for metal sorting and mining prospecting, as well as environmental and toxic metal. The Environmental Protection Agency (EPA, 2007) promoted (Palmer, 2011) in the 1990’s the development of portable XRF analyzers through grants awarded by the "Small Business Innovation Research and Environmental Technology Verification” programs. Thanks to this type of instruments, X-ray spectroscopy has undergone a growth in the field of conservation science during the second half of the 20th century (Sciutto, 2012). It is possible in this way to investigate a theoretically unlimited number of points, obtaining information on the composition and modification of the inorganic components present in a work of art, e.g. pigments, fillers, or degradation products.

TABLE 5.- Comparison of EDXRF and WDXRF Spectrometers (AXT PTY LTD X-Ray Fluorescence - XRF spectrometers; [9]; Beckhoff et al., 2006, pp 301–302; Brouver, 2010, p. 28)

| Aspect | WDXRF | EDXRF | Aspect | WDXRF | EDXRF |

|---|---|---|---|---|---|

| Elemental detection

range |

Be to U | Na to U | Energy resolution | Excellent ~ 20 to 150 eV | Poor ~ 150 eV |

| Spectral resolution | Excellent | Good | Power | Typically < 4 kW | Typically < 1 kW |

| Light element analysis | Excellent | Good | Sample capacity | High | Low |

| Rare earth analysis | Good | Difficult | Automation | Easy | Difficult |

| Detection limit | Optimized for all

elements in the detection range |

Good for light elements but suited, better to heavy elements. | Critical moving parts | Goniometers + Detectors | None to a few |

| Measurement time | Faster | Slower | Cost | Relatively expensive | Relatively inexpensive |

| Sensitivity | Reasonable for light elements,Good for heavy elements | Less optimal for light elements,Good for heavy elements | Measurement | Sequential/ Simultaneous | Simultaneous |

4 Advantages and Disadvantages of XRF

The advantages inherent in XRF are superior (Anzelmo and Lindsay, 1987) to those of any other spectrographic method: (i) X-ray spectra are relatively simple compared to optical spectra, thus minimizing interference of spectral lines; ii) the matrix effect (absorption/enhancement) is predictable and can be easily evaluated; iii) It is versatile, and the determinations are fast and accurate, so it is highly recommended as an analytical technique. Among its limitations we can highlight: i) difficulties encountered in analyzing light elements in liquids; (ii) relatively shallow penetration of solids; iii) it is necessary to have standards with the same physical form as the analyte; iv) the cost of the equipment is high requiring a large initial investment.

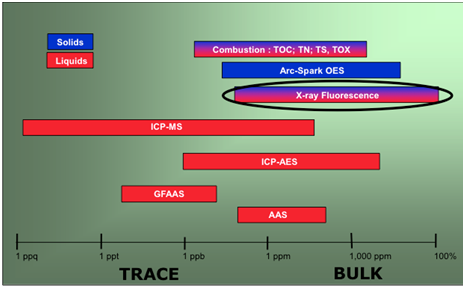

Among the drawbacks we can mention that the analyte may be influenced by the adsorption of the primary radiation and also by the fluorescence radiation produced. This results in a shallow layer of a few tenths of a millimeter deep, providing information on its composition. Conventional XRF in some applications does not rival in concentration range some other emission or absorption atomic techniques, such as ICP-MS (inductively coupled plasma mass spectrometry), ICP-AES (inductively coupled plasma atomic emission spectroscopy), or GFAAS (graphite furnace atomic absorption spectroscopy), as shown in Fig. 19, leading to (Marguí et al., 2007; Marguí et al., 2009) somewhat poorer precision and accuracy.

Sensitivity can be improved by TXRF (Klockenkämper and von Bohlen, 2015; Klockenkämper et al., 1992), where the primary X-ray photons, at very low displacement angles, are absorbed almost completely into thin samples on a very flat support. This avoids the high background radiation produced due to the dispersion of the sample support. Some limitations are also apparent in XRF when dealing with an aqueous sample, e.g. short linear range, the need to strictly match the standards to overcome the effects of the matrix, bubbles released from the solutions owing to an inappropriate filling of the sample holder, and heating of the solution.

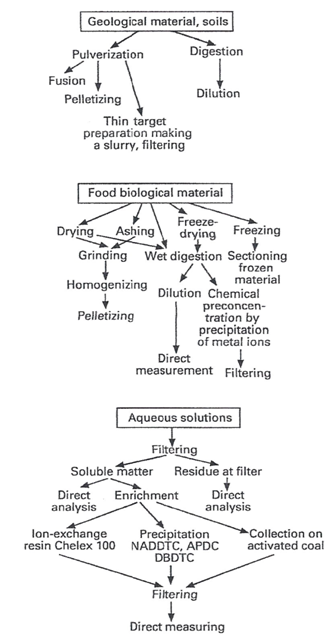

5 Sample Handling

Sample preparation is a crucial step (Yamada, 2014) in the XRF analytical procedure. Figure 20 shows an overview of typical sample preparation techniques (Streli et al., 2017) used in XRF. Among the aims pursued in sample preparationare: i) removal of interference; ii) preconcentration of the analyte; iii) converting the analyte into an appropriate detection form; iv) to provide robust and reproducible methods. Samples have to be representative of the whole sample since spectrometers only analyze the samples surface layer (Brouwer, 2010; van Grieken and Markowicz, 2002; Young et al., 2016). Most spectrometers use circular disks with a radius between 5 and 50 mm to measure the sample placed in a cup (Brouwer, 2010). Special caps with supporting films are used for the measurement of loose powder and liquids (Brouwer, 2010;Campbell et al., 2012; Morikawa, 2014; Moriyama and Morikawa, 2017; Takahashi, 2015). Diluents are sometimes necessary to get sufficient liquid. Liquids cannot be measured in a vacuum because they can evaporate; measuring them in air is possible, although the air absorbs much of the radiation, making it impossible to measure light elements. Therefore, the spectrometer chamber is filled with He gas, so liquids are not evaporated and the radiation is hardly absorbed. In recent years, sample preparation procedure for XRF analysis has undergone an important growth. As a matter of fact, sampling exerts a significant influence on the final quantitative result, being a topic at least as important as the technique itself.

Random (to be minimized) and systematic (that can be removed) errors arise from a variety of sources (Anzelmo, 2014), such as the counting of statistics, the power source, the spectrometer, the macro sampling and specimen preparation processes, calibration standards, correction algorithms, as well as laboratory environment conditions, i.e. temperature, humidity, vibration or dust. Advances in stability of generators, tubes and electronics, the accuracy of goniometers, and the available software to apply empirical and theoretical correction algorithms leave standard selection, sampling and specimen preparation as the largest sources of error.

General rules that lead to the highest accuracy (Anzelmo et al., 2014) include: i) representative sample specimen; ii) homogeneous and flat specimen; iii) similarity between the standards and the unknowns; iv) good reproducibility specimen preparation; and v) specimen stability before and during analysis. The following factors affect the physico-chemical properties of the specimen: i) infinite thickness (i.e., it should not affect the analysis); ii) effective layer thickness (calculated by modern software ad changing with the matrix); iii) surface film absorption characteristics, dealing with liquids samples; iv) particle size effects (loose an pressed powders) such as grain size, intermineral and mineralogical effects, respectively; v) grinding curve analysis (pressed powders); and vi) groove depth, smearing, and groove orientation (metals).

In XRF,the sample preparation procedure has a strong influence on the final quantitative result (Marguí et al., 2016). Standards must be reproducible, having similar physical properties (e.g. comparable mass attenuation coefficient, density, particle size and particle homogeneity, and matrix characteristics as the unknown). The closer the standards are to these requirements, the more accurate the analysis will be. An inadequate choice of a sample from the bulk material (ore deposits, ship cargo holds, quarries, coal seams, rail cars, manufacturing process, and production lines) or an inappropriate sample preparation can lead to introduce large systematic errors in the analytical procedure.

An important factor to take into account also during specimen preparation method (Rouessac and Rouessac, 2007) is the possible re-absorption of the fluorescence emitted by the elements that make up the matrix. Result obtained may thus be underestimated by optical quenching, or overestimated if a secondary excitation of other elements containing in the sample is caused bysome of the X-ray fluorescence. So, sample handling is a crucial step in the ultimate accuracy of any X-ray determination. Based on the handling treatment, we can generally establish (Jenkins, 2000a) three main categories:

- Those that involve a simple pre-treatment, e.g. homogeneous powders, bulk metals (Moriyama and Furusawa, 2016) or liquids.

- Those need significant pre-treatment (e.g. heterogeneous samples, samples requiring matrix dilution or samples with particle size effects).

- Those that entail special handling treatment (e.g. limited size, pre-concentration or prior separation or radioactive samples).

If samples may be properly dissolved, they are best handled as liquids (Marguí, 2014; Moriyama and Morikawa, 2017). The sample handling of liquid samples is very simple, just a small volume of the sample is placed in a type of vial whose bottom is transparent to X-rays (a film of polypropylene or mylar (polyester)). So that the sample appears infinitely thick to the primary X-ray, its depth should be at least 5 mm. In the case of hydrocarbons, the sample depth of absorption can be as much as 1 cm. To dissolve the samples, solvents that do not contain heavy atoms should be used, for example, water and nitric acid are superior to hydrochloric or sulphuric acid. The main technical drawback of liquid samples is the high X-ray scatter background, leading to too low signal-to-noise ratio. To overcome this problem, different extraction techniques (Moradi et al., 2015) have been proposed prior to XRF analysis.

In some cases, solid samples require only a minimum sample preparation, like cleaning and polishing. But, in many other cases, a transformation prior to the measurement is needed (Rouessac and Rouessac, 2007). Heterogeneous bulk solids are generally (Jenkins, 2008) the most difficult kind of sample to handle. Among the most common methods of solid sample preparation are pressed powder pellets and fused glass disks (Takahashi, 2015; Watanabe, 2015; Watanabe, 2016). The first method uses a hydraulic press to pellet formation, being an alternative to the fusion technique. A wax (an organic polymer formed from light elements) is added in order to ensure the cohesion of the pellet. Pressed powder pellets have matrix effects increasing analytical uncertainties, particularly in light elements. In the second method (fusion), a little of the sample is mixed with lithium tetraborate (Li[math]_{2}[/math]B[math]_{4}[/math]O[math]_{7}[/math]) and different additives, obtaining with the aid of an electric oven a glass, named pearl, constituting a matrix of light elements, transparent to X-rays. The use of fused glass method allows the determination of major, minor, and trace elements in a wide range of materials. This method is an advantage in the case of samples that are difficult to dissolve, like refractory samples.

During the melting process (Brouwer, 2010), a part of the sample can evaporate as H[math]_{2}[/math]O or CO[math]_{2}[/math], losing part of its contents. Elements like S, Hg and Cd are prone to escape from the sample during heating, giving what is known as “loss on ignition” (LOI). Total LOI is determined by weighing the sample before and after fusion.It is necessary to know which kind of flux material and how much is required to carry out the analysis in order to make a proper correction. Light elements like Li, commonly used as flux materials (Li[math]_{2}[/math]B[math]_{4}[/math]O[math]_{7}[/math]), cannot be measured.

Granules and powdered materials, oils, bones, and liquors of high salt content are directly analysed under a helium back-flush after pouring in a proper sample cup, if reproducibility is not affected by small variations in packing density. Solid material in liquids or gases must be filtered out and the filter mounted in a suitable holder and analyzed as a solid. There are two kinds of sample holders: cassettes for bulk solid samples, and cells for loose powders, small drilling, and liquids. Polymer films used to cover the cell opening must be low in trace element impurities, strong enough to hold the sample without breaking, thermally stable, and chemically inert (Robinson, 2005). Powders may also be pressed into a wafer, as long as they are previously diluted with a material of low absorption to avoid matrix effects (powdered starch, lithium carbonate, lamp-black, or gum Arabic). Metallurgical samples should be cast in the form of a cylindrical billet (with a ground flat surface for analysis). In order to get the highest precise results, ceramics, refractories, rocks, ores, soils, etc., requires crushing and grinding and prepared in a form reproducible for analysis, i.e., compressed power pellets or glass disks.

Another problem frequently found in bulk materials, large pieces of rock, etc., is their size and heterogeneity (Jenkins 2000a, 2008). Once the sample is received, if it is heterogeneous, it is necessary to render the sample homogeneous prior to the analysis.

As we mentioned above, if the concentration of analyte in liquids or solutions is too high or too low, it is necessary to carry out (Moradi et al., 2015) a step of dilution or preconcentration (e.g., evaporation, solid-phase extraction (SPE), electrodeposition, or classical liquid-liquid extraction, LLE) to bring the analyte concentration within the properly range. Recent analytical techniques used to that end in XRF include (Marguí et al., 2010; Moradi et al., 2015): SPE (disc, quasi-solid, particles, and electrodeposition); or liquid-phase extraction (supported liquid membrane and liquid-phase microextraction).

In SPE the analyte contained in a portion/solution put in contact with a solid-phase sorbent, is adsorbed in a selective way onto the surface of the solid phase. In any other methodology, an elution step is usually required to recover the analyte from the sorbent. XRF implies instead the direct quantification of the element in the solid sorbents. This avoids the use of chemicals and minimizes the sample handling.

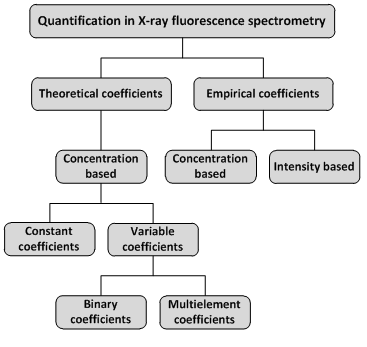

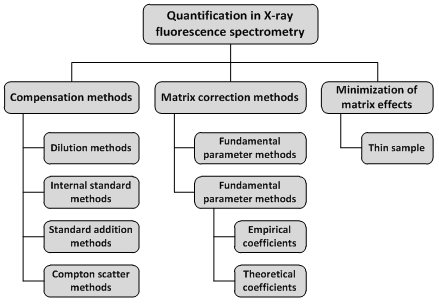

Conventional LLE involves large amounts of toxic organic solvents, being also time-consuming, tedious, and a multi-stage operation. It is challenging in recent years to use non-toxic and environmentally friendly analytical procedures (Moradi et al., 2015) consistent with green chemistry postulates. Solvent-free and/or miniaturized extraction methods have been developed in accordance with modern guidelines.